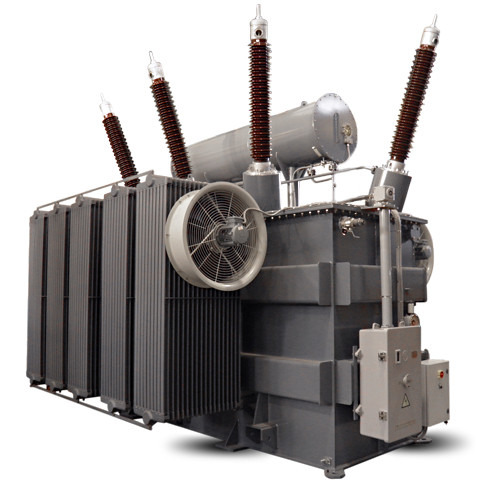

Oil immersed power transformers

For European market ,the calculation is made according to Ecodesign regulation, norms EN 50588-1.

The core is made of high permeability crystal oriented steel sheet low loss, in a step section with 45° joints step-lap assembly, and is fitted with cooling channels.

The winding conductors are all made of E-CU 99,9% electrolytic copper.

According to the design of the transformer, windings can be continuous or interleaved disc, simple or multiple helix.

Cooling channels are made with duly shaped rods and flow guide rings. Tappings are provided on the HV windings, controlled either by means of an off circuit switch or an on load tap changer.

The windings are dried in autoclave in order to reach exact dimensions and avoid successive inelastic failure. The complete transformer is closed in the tank and filled with oil in vacuum conditions. The tank is normally of the vacuum type. Cooling is made by means of tank mounted radiators: mainly used are the bolt on, detachable type; some times welded solution is used. The units can be fitted with fans or pumps to increase the rating of the transformer. The transformers are capable of operation at output in excess of nominal rating in accordance with IEC 354.

When dimensional considerations do not permit unit to be dispatched with insulating liquid, arrangements are made for filling the transformer tank with inert gas, or the dispatching of radiators and conservator detached. The transformers can be equipped with specific accessories in addition to standard ones, such as overpressure valve, conservator with diaphragm, current transformers, winding temperature indicator, cable box, centralization - marshalling box etc.

When required, on site erection can be carried out by our skilled personnel.

-

Technical features

Power MT Tension AT Tension Frequence Standards from 5 MVA to 45 MVA ONAN

(63MVA ONAF)11 / 15 / 20 / 30 / 52 / 70 KV 90, 110, 123, 132, 150 KV 50 - 60 Hz IEC 60076-13 / IEEE 57.12.01 In addition to distribution transformers ELETTROMECCANICA COLOMBO manufactures power transformers either for general purposes (reducing-increasing voltage on main grid, feeding auxiliary transformers, transferring to the grid the own produced current) and for specific purposes (industrial transformers, autotransformers, insulation transformers, starting transformers, transformers for testing ..). These general purpose transformers normally are converting high voltage to medium voltage (HV/MV) or medium voltage to medium voltage (MV/MV). For specific transformers, the progress achieved by power electronics has led to frequent use of converters (6-12—24 pulse) for the drive of various types of machines (pumps, ventilators, motors..).

The transformers for this use are designed from our technical department as stated from IEC 61378-1 norms, taking into account the type of work, the type of converter, the type and number of harmonics.

Customer requirements are defined in all electrical and mechanical characteristics, load factor, ambient conditions, service factor. These elements are verified and deepened with suggestions for better balancing technical and economic aspects.

ELETROMECCANICA COLOMBO has achieved a large experience in these sectors with a great quantity of transformers in use since years with satisfactory results. For all transformers the technological ability connected with a quality assurance system certified ISO9001 guarantee a reliable product with an expected lifetime span in normal condition over 30 years.Transformers with no load tap changer

The no load tap changer is used to vary the transforming ratio on M.V. side with the transformer out of duty and with fixed steps (for instance 2,5%). If necessary, the handle of the tap-normally on the cover-can be placed on tank side, with manual or motorized drive.

Transformers with on load tap changer

The on load tap changer (OLTC) is used to vary the voltage ratio with the transformer on duty providing uninterrupted regulation. The on load tap changer is activated by a motor drive. Drive shafts and bevel gear units mechanically connect the motor-drive to the on load tap changer. An electronic voltage regulator is used for sensing the voltage variation and to operate automatically the motor drive. The OLTC installed in our power transformers are of technically advanced design.

-

Download

Brochures

Download brochureDati tecnici

Technical data request